Fire Hydrant Valve Assembly

Fire hydrant assemblies shall be designed to meet the requirements of this subsection and all other requirements listed in this section.

Fire hydrant valve assembly. Assemblies to your specification. Anubar test valve assembly. Single point booster valves. A fire hydrant system block plan is an indelible diagram mounted within the booster cabinet pump room and fire control room that illustrates the primary features of the fire hydrant system including the water supply location dimensions location capacity of each water storage or tank location quantity of each valve location of each pump pressure flow rating of the pumps location.

This may be as simple as an attack hydrant requirement such as a dual hydrant riser or a more complicated fire brigade quad booster point complete with feed hydrants isolating and check valves. Assemblies booster hydrant booster and hydrant assemblies consist of arrangements of valves pipe work to suit specific site fire protection needs. Stainless steel flexible pump connectors. Fire hydarant landing valves.

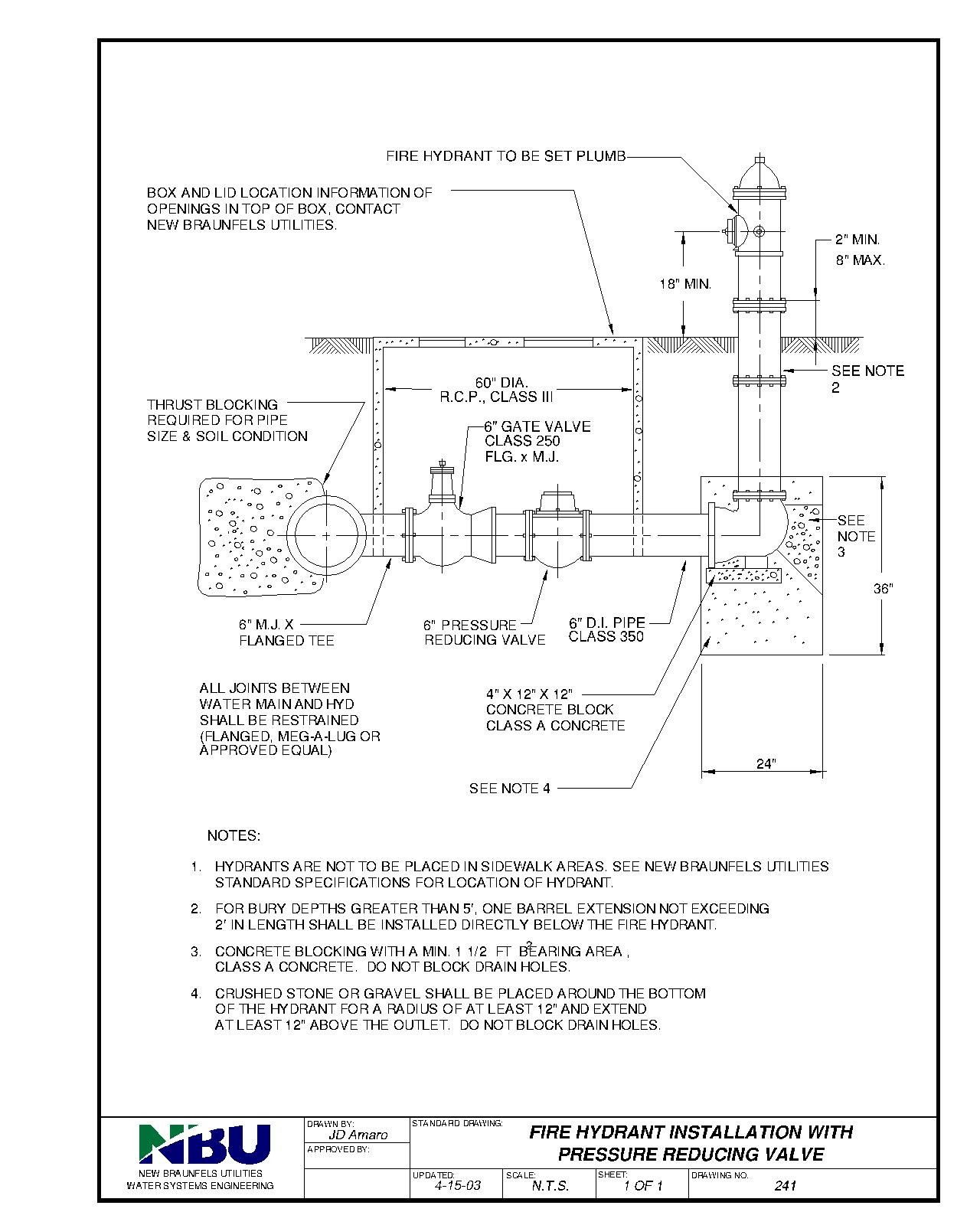

There are 3 main types of hydrant assemblies a perpendicular assembly a parallel assembly and an assembly over the main. Fire hydrant suction booster assemblies. Waste test valve. Fire hydrant assemblies shall be designed to withstand the working pressures shown on the plans or a design working pressure of 150 psi whichever is greater.

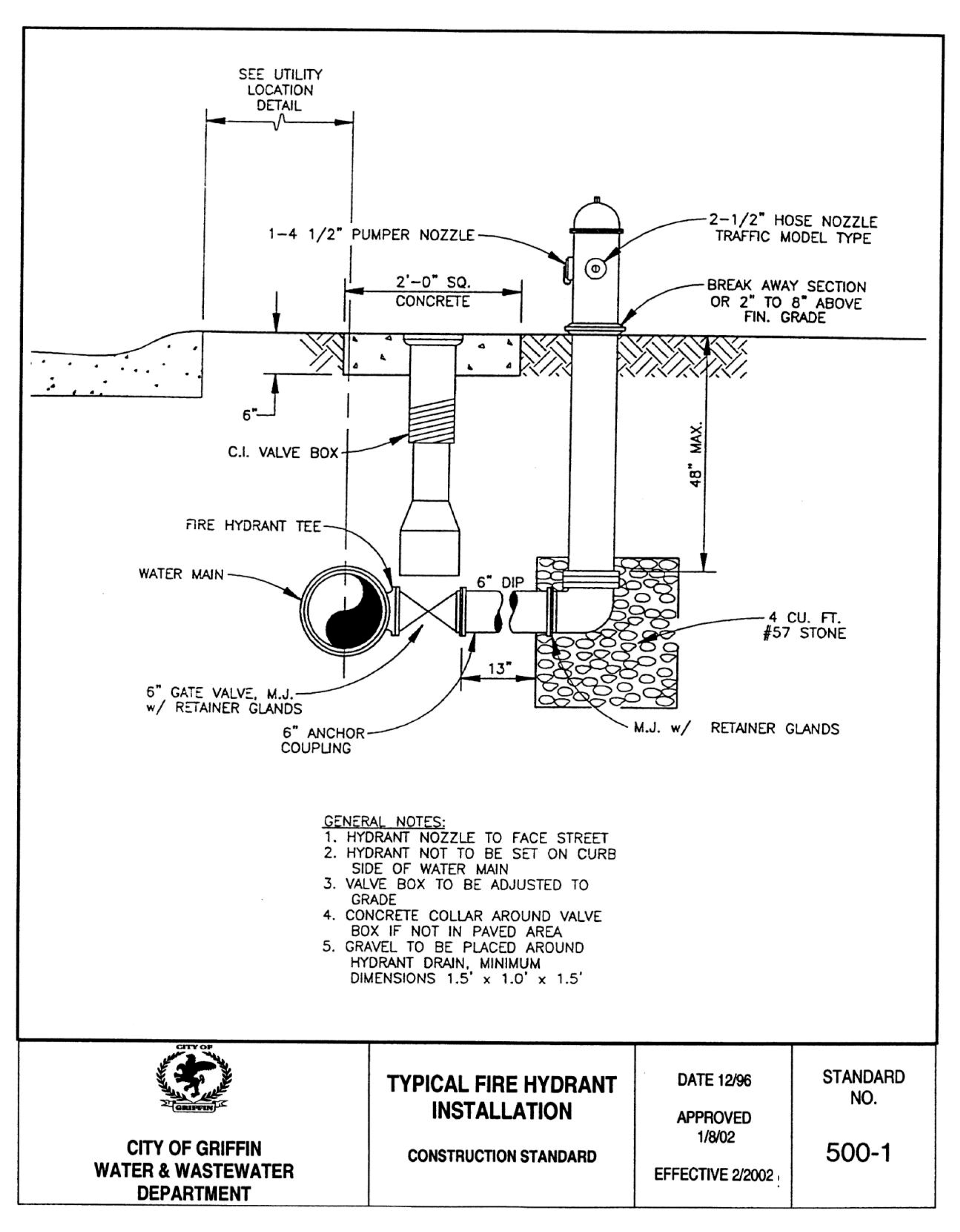

Fire hydrants are typically coupled with a watch or gate valve which shuts off the water source from the main line allowing maintenance repair or replacement of the hydrant.